Home > Products > Mixing Equipment > Factory Price High Shear Homogenizer Vacuum Emulsifying Machine Aloe Vera Gel Making Machine

Factory Price High Shear Homogenizer Vacuum Emulsifying Machine Aloe Vera Gel Making Machine

Vaseline Making Machine Ointment Vacuum MixerProduction of each machine in belowSemi-automatic production line,Water treatment EDI,ultraviolet(alternative) water tank Ozone generator,pump(alternative) homogenizer emulsifier material tank semi-automatic filling machine semi-automatic capping ma......

Send Inquiry

Product Description

Vaseline Making Machine Ointment Vacuum MixerProduction of each machine in below

Semi-automatic production line,

Water treatment → EDI,ultraviolet(alternative)→ water tank → Ozone generator,pump(alternative) → homogenizer emulsifier → material tank → semi-automatic filling machine → semi-automatic capping machine → semi-automatic labeling machine → ink printer → conveyor(alternative)

Fully automatic production line,

Water treatment → EDI,ultraviolet(alternative) → water tank → Ozone generator,pump(alternative) → homogenizer emulsifier → material tank → automatic filling and capping machine → automatic labeling machine → ink printer

Related products :

Water treatment , mixing machine , filling machine , storage tank , capping machine , labeling machine , ink printer , conveyor table , vacuum emulsifying mixer ......

Semi-automatic production line,

Water treatment → EDI,ultraviolet(alternative)→ water tank → Ozone generator,pump(alternative) → homogenizer emulsifier → material tank → semi-automatic filling machine → semi-automatic capping machine → semi-automatic labeling machine → ink printer → conveyor(alternative)

Fully automatic production line,

Water treatment → EDI,ultraviolet(alternative) → water tank → Ozone generator,pump(alternative) → homogenizer emulsifier → material tank → automatic filling and capping machine → automatic labeling machine → ink printer

Related products :

Water treatment , mixing machine , filling machine , storage tank , capping machine , labeling machine , ink printer , conveyor table , vacuum emulsifying mixer ......

Factory price High Shear Homogenizer Vacuum Emulsifying Machine Aloe Vera Gel Making Machine

Mixing Equipment

Mixing is an important part of pharmaceutical cream production. Operations can include dissolving solids and powders, preparing emulsions, combining raw materials, enabling chemical reactions, and milling active pharmaceutical ingredients (APIs), to name a few. Efficiency and accuracy are key when in the mixing process to ensure dosage accuracy, stability, appearance, and texture. Therefore, selecting the proper type of mixer for the right application is an important part of the instrumentation process.

Mixing is an important part of pharmaceutical cream production. Operations can include dissolving solids and powders, preparing emulsions, combining raw materials, enabling chemical reactions, and milling active pharmaceutical ingredients (APIs), to name a few. Efficiency and accuracy are key when in the mixing process to ensure dosage accuracy, stability, appearance, and texture. Therefore, selecting the proper type of mixer for the right application is an important part of the instrumentation process.

Hydraulic Lifting and Tilting System are used for material discharge and cleaning, easy and convenient operation

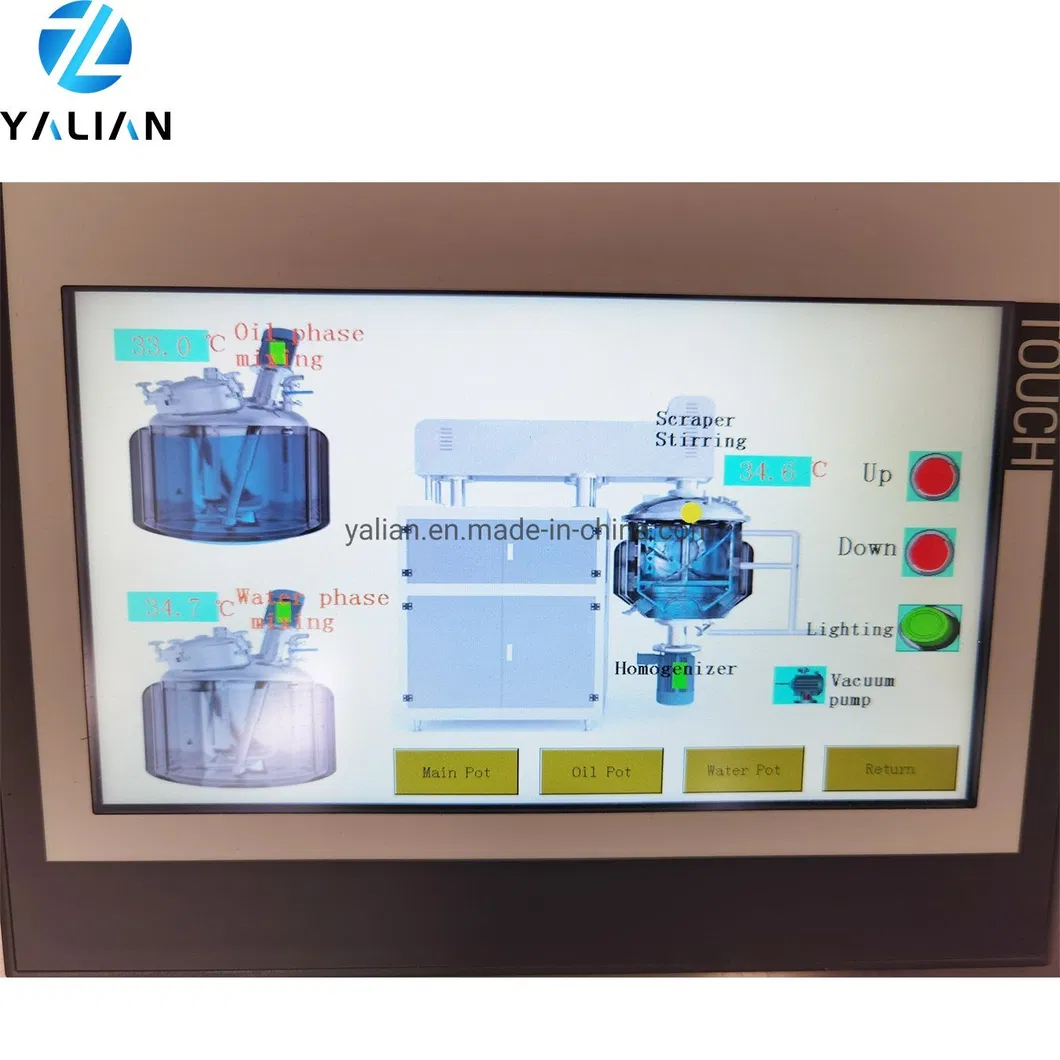

Electric Cabinet

SUS304 control panel: button / PLC touch screen (option)

Ampere meter, Voltmeter

Real-time Temperature display

Mixing system control (frequency control)

Vacuum system control

Hydraulic lifting system control

SUS304 control panel: button / PLC touch screen (option)

Ampere meter, Voltmeter

Real-time Temperature display

Mixing system control (frequency control)

Vacuum system control

Hydraulic lifting system control

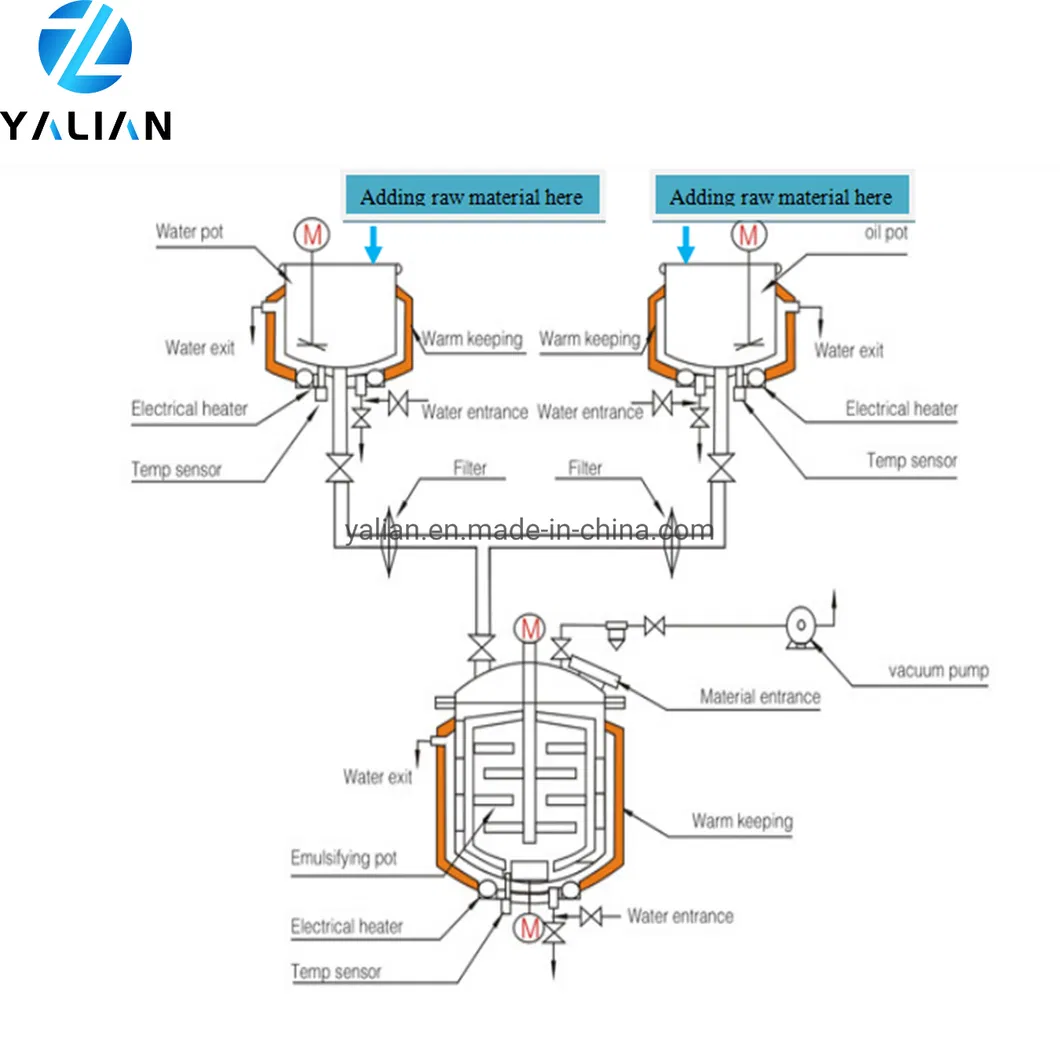

Water and Oil Pot

Machine equipped A set of water and oil pot

Water pot capacity: 10-5000l, Oil pot capacity: 10-5000l

Power: 0.37-22kw, Siemens motor, Speed: 1440RPM

Electric heating by Water or Conduction Oil

Mixing: High shearing DISPERSER plates with baffle on wall

Half open hinged lid for easy operation

Machine equipped A set of water and oil pot

Water pot capacity: 10-5000l, Oil pot capacity: 10-5000l

Power: 0.37-22kw, Siemens motor, Speed: 1440RPM

Electric heating by Water or Conduction Oil

Mixing: High shearing DISPERSER plates with baffle on wall

Half open hinged lid for easy operation

Frame Wall Scrapper Mixer

SUS316L Wall scrapper mixerPTFE scraper

Fixed propeller, 45degree blades on opposite angles to make sure mixture complete

Siemens motor drive, 0-65rpm with variable speed controlTWO WAYS wall scrapper mixer

HELIX scrape mixer(OPTION)

SUS316L Wall scrapper mixerPTFE scraper

Fixed propeller, 45degree blades on opposite angles to make sure mixture complete

Siemens motor drive, 0-65rpm with variable speed controlTWO WAYS wall scrapper mixer

HELIX scrape mixer(OPTION)

Lid Parts

Material suction inletVacuum presssure gauge

Vacuum port, Vent filter

Positive pressure inlet

Perfume hopper

CIP spray ball, LED Light

Sight window

Material suction inletVacuum presssure gauge

Vacuum port, Vent filter

Positive pressure inlet

Perfume hopper

CIP spray ball, LED Light

Sight window

Why the tank with homogenizer is best ?

Emulsification is the process of mixing two liquids that are difficult to mix. The main purpose of emulsification is to disperse the discontinuous phase into smaller droplets. The rotor-stator device is particularly suitable for emulsification tasks. The combined action of high shearing force and high expansion force in the mixing head makes the droplets small. In addition, the large turbulence enables the rotor-stator device to help transport emulsifier molecules quickly to the reformed surface.

Emulsification is the process of mixing two liquids that are difficult to mix. The main purpose of emulsification is to disperse the discontinuous phase into smaller droplets. The rotor-stator device is particularly suitable for emulsification tasks. The combined action of high shearing force and high expansion force in the mixing head makes the droplets small. In addition, the large turbulence enables the rotor-stator device to help transport emulsifier molecules quickly to the reformed surface.

Lifting vacuum emulsifier

The lifting external circulation vacuum emulsifier is specially designed by Planck for the production of products with high viscosity and high emulsification requirements in the cosmetics and pharmaceutical industries. Its biggest features are:

1. The material can be continuously emulsified in circulation;

2. Emulsify materials with high viscosity more thoroughly, without dead ends;

3. The external circulation emulsifier can replace the conveying pump for discharging, and can be cyclically cleaned.

The mixing adopts forward and reverse double scraping side mixing, with high-speed external circulation emulsifying head design.

The lifting external circulation vacuum emulsifier is specially designed by Planck for the production of products with high viscosity and high emulsification requirements in the cosmetics and pharmaceutical industries. Its biggest features are:

1. The material can be continuously emulsified in circulation;

2. Emulsify materials with high viscosity more thoroughly, without dead ends;

3. The external circulation emulsifier can replace the conveying pump for discharging, and can be cyclically cleaned.

The mixing adopts forward and reverse double scraping side mixing, with high-speed external circulation emulsifying head design.

After the materials are mixed and reacted by heating and stirring in the water pot and oil pot, they are sucked into the emulsifying pot by the vacuum pump, and stirred through the center of the upper part of the emulsifying pot. , So that the captured materials continuously produce new interfaces, and then through the cutting, compression, and folding of blades and rotating blades, they are stirred and mixed and flow down to the homogenizer below the pot body, and the materials are cut by high-speed rotation During the process of strong shearing, impact, turbulence, etc. between the wheel and the fixed cutting sleeve, the material is cut in the shearing seam and quickly broken into 200nm-2um particles. Because the emulsification pot is in a vacuum state, the material is The air bubbles generated during the stirring process are drawn away in time.

Characteristic

·With hydraulic lifting system, the lid can be raised and lowered freely.

·The mixing system adopts double scraping side mixing frequency conversion speed regulation, which can meet the production requirements of different processes.

·Advanced homogenizer, unique structure, reliable sealing (mechanical seal is German Burgman), emulsification speed is 0-3500 rpm (German Siemens frequency converter)

·The material is imported SUS304 or SUS316L stainless steel, and the tank and pipes are mirror-polished, which conforms to GMP specifications.

·Vacuum defoaming can make the materials meet the sanitary and aseptic requirements, and vacuum suction can be used to prevent dust from flying for powder materials.

·According to process requirements, the tank can heat or cool materials, and the heating method can be steam or electric heating according to customer requirements.

The standard configuration

Main bowl, water tank, oil tank

Vacuum pump and synchronous solenoid valve

Emulsifier and material filter

Hydraulic lifting system and mixing system

Stainless steel operating platform

Frequency converter and electric control box

DBI recyclable homogenizer

Company introduce :

Guangzhou Yalian is a large-scale company specialized in design, manufacturing, installation and commissioning of daily chemical, chemical, food and pharmaceutical machinery, as well as water treatment equipment. With powerful technical strength, complete inspection facilities, unique and advanced technique as well as great varieties of products, the enterprise strictly implements ISO9001 standard management.

RFQ:

1. Q: Are you a manufacturer or just a trading company?

A: Guangzhou Yalian cosmetics machinery equipment company is one of the top technology-oriented machinery manufacturer in China.

2. Q: I am new in this field , can you recommend the whole production line?

A: We can recommend you the whole production line depends on what products you will make:

(1). If for paste or cream product, the following machine we will recommend you:

RO water treatment equipment → Vacuum homogenizer → Storage tank → Paste filling machine or Heating mixing filling machine → Capping machine → Labeling machine → Inkjet printer → Shrink film packing machine etc.,

(2). If for liquid product, the following machine we will recommend you:

RO water treatment equipment → Blending tank → Storage tank → Liquid filling machine → Capping machine → Labeling machine → Inkjet printer → Shrink film packing machine etc.,

(3). If for Perfume, the following machine we will recommend you:

RO water treatment equipment → Perfume making machine → Perfume storage tank → Perfume filling machine → Perfume crimping machine → Perfume collar machine → Inkjet printer → Shrink film packing machine etc.,

(4). There are Full automatic production line and Semi automatic production line for your option.

3. Q: What is your payment term?

A: We usually pay by T/T., 40% deposit after sales confirmation, 60%before delivery.

4. Q: What is your delivery day?

A: Our delivery day is about 15-30 days after receive the deposit.

5.Do you have requirement of capacity?

Related Category

Machinery for Food, Beverage & Cereal

Metallic Processing Machinery

Laser Equipment

Mould

Textile Machinery & Parts

Paper Machinery

Chemical Equipment & Machinery

Cutting & Fold-bend Machine

Mixing Equipment

Rubber Machinery

Machinery for Garment, Shoes & Accessories

Crushing & Culling Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.