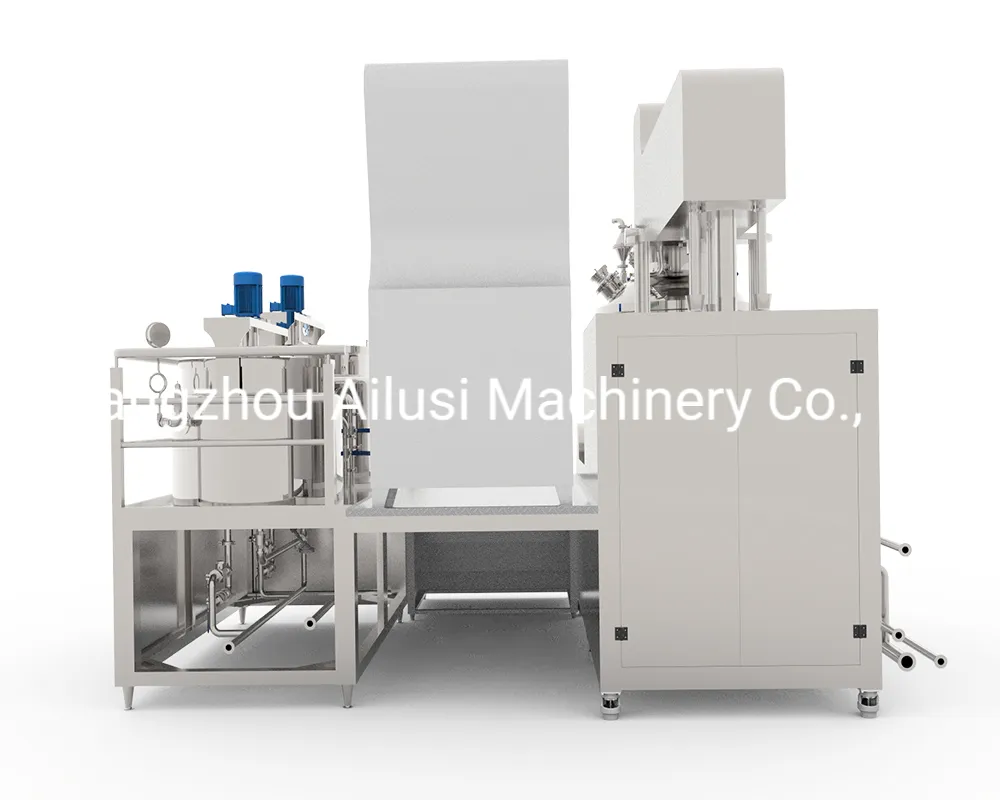

Batch Vacuum Homogenizer

PProduct Description: The machine is suitable for the production of various kinds of paste, cream products in cosmetic factories and pharmaceutical factories. Specially designed for the production of stable emulsions creams, milk, gels, balms, lotions, ointments, toothpaste, etc. having extremely......

Send Inquiry

Product Description

The machine is suitable for the production of various kinds of paste, cream products in cosmetic factories and pharmaceutical factories. Specially designed for the production of stable emulsions creams, milk, gels, balms, lotions, ointments, toothpaste, etc. having extremely small particles for chemical, cosmetics, pharmaceutical, and food industries

Standard configuration

- Emulsifier, water phase tanks, oil phase tank

- Vacuum pumps and sync solenoid valves

- Emulsifier and material filter

- Hydraulic lifting system and mixing system

- Stainless steel platform

- Inverter and electrical control box

Working Principle

The materials in the water-phase tank and oil-phase tank are heated up and stirred. After they are thoroughly mixed, they will be transferred to the emulsifying tank by the vacuum pump. The material will be stirred by the upper part of the central paddle, combined with the PTFE scraper sweeping the wall, the material will be stirred thoroughly and meanwhile be pushed down to the emulsifier at the low part of the central axle. With a very high-speed emulsifying effect, the material will be seriously cut, sheared, and cracked into 200nm - 2um particles. The bubbles that appear during the process will be sucked out promptly in the vacuum status in the tank.

Technical Parameters:

capacity (L) | Agitator power (kW) | Speed (rpm) | Homogenizer power (kW) | Speed (rpm) | Oil/Water tank (L) | Agitator power (kW) | Speed (rpm) | Hydraulic (KW) |

50 | 1.5 | 0~75 | 2 | 0~3600 | 20/45 | 0.37/0.37 | 0~1440 | 0.75kw |

100 | 2.2 | 0~75 | 3 | 0~3600 | 40/90 | 0.55/0.55 | 0~1440 | 0.75kw |

200 | 3 | 0~75 | 5.5 | 0~3600 | 80/180 | 0.75/0.75 | 0~1440 | 1.1kw |

300 | 4 | 0~75 | 5.5 | 0~3600 | 120/270 | 1.1/1.1 | 0~1440 | 1.5kw |

500 | 4 | 0~75 | 7.5 | 0~3600 | 200/450 | 1.5/1.5 | 0~1440 | 1.5kw |

1000 | 5.5 | 0~75 | 11 | 0~3600 | 400/900 | 2.2/2.2 | 0~1440 | 2.2kw |

2000 | 7.5 | 0~75 | 15 | 0~3600 | 800/1800 | 2.2/2.2 | 0~1440 | - |

3000 | 11 | 0~75 | 18.5 | 0~3600 | 1200/2700 | 3/3 | 0~1440 | - |

Main features:

1) Consist of the main emulsifying mixer, water pot, oil pot, vacuum pump, etc

2) Ointment making machine adopts advanced world famous brand components in pneumatic parts, electric parts, and operation parts.

3) High-quality SUS304&316L material, internal and external mirror polish of homogenizer mixer.

4) High effection homogenizer, 2μm smooth finish

5) Vacuum emulsifying mixer machine applies to cosmetics, pharmaceutical, food, etc industries

Details pictures:

Factory:

Project: