Batch Powder Production Horizontal Coulter Mixing Machine

Product DescriptionPlough mixer is characterized by high mixing precision, and wide application to food, chemical industries, and building lines. The major sections of a mixer are barrel, plough shears, feeding ports, discharging port and driven unit.Plough shear or sloping blade is set on the main ......

Send Inquiry

Product Description

Plough mixer is characterized by high mixing precision, and wide application to food, chemical industries, and building lines. The major sections of a mixer are barrel, plough shears, feeding ports, discharging port and driven unit.

Plough shear or sloping blade is set on the main shaft. When the plough shear mixer is on the operation, the special mixing structure makes the material to be mixed continuously! The dead corner is absolutely avoided under the simultaneous radial and longitudinal movement, thus high accuracy mixing effect is achieved.

Design capacity:50-30,000L

Materials Specific Gravity ≤5g/cm3

Mix time:8-15 minutes

Driven power:3KW-132KW

Equipment materials:304,321,316L,carbon steel

Technical Data

| model | Power(kW) | Speed(rpm) | Fly- cutter Speed(rpm) | Capacity(L) | Overall Size(mm) | Weight (kg) |

| LDH-100 | 3 | 85 | 3*1 | 30-60 | 1500*500*700 | 400 |

| LDH-500 | 7.5 | 82 | 3*2 | 150-300 | 2500*800*1200 | 1100 |

| LDH-1000 | 11 | 62 | 3*2 | 300-600 | 2700*1000*1450 | 1600 |

| LDH-2000 | 15 | 50 | 3*3 | 600-1200 | 3300*1200*1700 | 2500 |

| LDH-3000 | 18.5 | 50 | 3*3 | 900-1800 | 3800*1300*1950 | 2900 |

| LDH-4000 | 22 | 42 | 3*4 | 1200-2400 | 4100*1400*2000 | 4000 |

| LDH-5000 | 30 | 42 | 3*4 | 1500-3000 | 4200*1500*2000 | 4500 |

| LDH-6000 | 37 | 42 | 3*4 | 1800-3600 | 4500*1700*2000 | 6000 |

| LDH-8000 | 45 | 33 | 3*5 | 2400-4800 | 5000*1800*2200 | 7500 |

| LDH-10000 | 55 | 33 | 3*5 | 3000-6000 | 6000*1900*2500 | 8500 |

| LDH-15000 | 75 | 26 | 3*6 | 4500-9000 | 7000*2100*2800 | 9800 |

| LDH-20000 | 90 | 26 | 3*8 | 6000-12000 | 8000*2400*3000 | 13800 |

| LDH-30000 | 132 | 20 | 3*8 | 9000-18000 | 10000*2600*3500 | 18500 |

Note:

The data can be used for reference only

The above list max processing capacity is calculated as per powder with specific gravity 1 as a medium.

The model selection should depend on the comprehensive factors such as materials viscosity, specific gravity, etc

Product application

The material can be carbon steel, 304, 316L, and 321;

Powder contact parts suggest stainless steel

Multifield surface treatment include mirror polish, sandblasting and

Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

The driven unit, power, and output speed are varied according to different raw material, starting method, and processing.

Options for motor: general motors, explosion-proof motors,

Heavy duty gear reducer with a direct connection

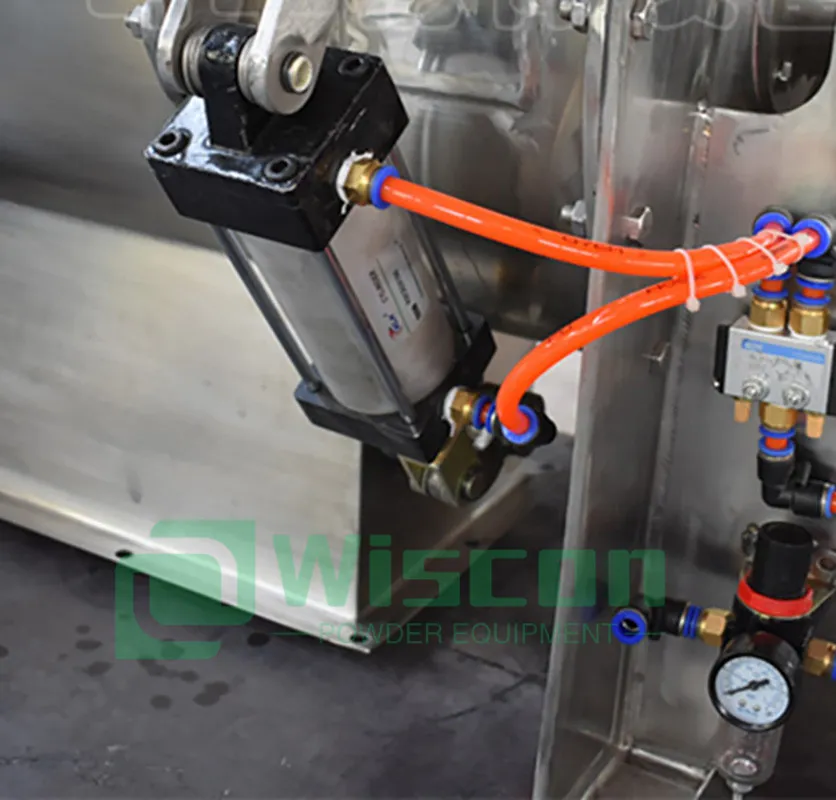

Standard valve for horizontal mixer is pneumatic planar flap valve. When close the valve, the planar flap match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect.

The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, butterfly valve, etc.

About Wiscon

We are the professional powder equipment supplier which applied in chemical, pharmaceutical, agrochemical, food, new material, etc. industries.

We can supply a perfect turnkey project with design, manufacture, installation, commissioning & after-sale service.

Our outstanding reputation for products high-quality, durable, customized solutions is widely recognized. We partner with our customers and help them to keep their operations safe and controlled.

Our core values―respect, integrity, Excellent quality, close proximity to our customers―guide our actions and behavior every day.

Frequently Asked Questions

Q: What's the quality of your products?

A: First of all, we select qualified parts supplier, then We have strictly quality control during production, You can rest assured with the quality absolutely.

Q: What to do if the machine has a problem?

A: We provide 24-hours customer hotline service and provides technical support free of charge within or after warranty; If beyond 12 months, customers only bear the freight and accessories cost.

Q: How long is the warranty for your equipment?

A: Our warranty period is 12 months.

Q: What is your payment term?

A: Our payment term is: T/T or LC. Also, other payment could be negotiable;

Q: Could you accept customized design?

A: All our products designed base on customer requirements and site conditions, we can supply customized designs for better machinery working.

Q: how to reach your company?

A: We located in Wuxi city, Jiangsu province, our factory is close to shanghai airport, about an hour, if you are to visit the factory. We can pick you up at the airport. Welcome to our company.

Q: How to choose the suitable powder blender equipment?

A: The proper selection of the powder blender depends on the following requirements:

1) What material you want to mix, is it dry? what is the size of the feed material?

2) What capacity you expect by mixing machines? (kg/h)

3) What mesh or mm or micron(size) of the powder you want?

4 ) What about your local voltage? For example, 380V 50hz 3p; 440V 60Hz,3p; 220V...